In a recent interview, Ariana Lynn, Principal Analyst at The Fast Mode spoke to Mithun Mathew, Product Specialist at Phoenix Contact Middle East on the impact of traffic visibility on modern IP networks. Mithun joins us in a series of discussions with leading networking, analytics and cybersecurity companies, assessing the need for traffic filtering technologies that can deliver real-time, granular application awareness. The series explores how advanced analytics power various network functions amidst the rapid growth in traffic and applications.

Ariana: How do your solutions and products fulfill the demands of today's networks?

Mithun: We help organizations decouple networking solution requirements from hardware that needs to host this solution, especially for harsh environments. For example, in any installation environment, deep packet inspection (DPI) technology for networks requires physical hardware to host such an application. Phoenix Contact can provide such a platform, especially if the installation is in a harsh environment such as a factory floor, oil rig, process plant, or electrical substation.

Ariana: How effective is DPI technology in addressing today's traffic complexities? What is your view on commercial DPI vs open-source DPI?

Mithun: From an end customer perspective, we have seen an increasing number of DPI technology installations in Critical Infrastructure and Industrial Networks. Hence DPI is important.

The literature on the hardware specification requirements for different open-source DPI installations should be clear and available. This will help us to propose the correct platform for installing open-source DPI software. From a hardware requirement perspective, commercial DPI solution providers have well-documented hardware specifications. We hope open-source DPI proponents will also consider this.

In general, support for open-source software is of concern as compared to commercial software. This could impact decisions when we are looking for specific installations in critical or industrial infrastructure.

Phoenix Contact is a global market leader and innovator in electrification, networking, and automation on the path to a smart world. Mithun Mathew is a Product Specialist at Phoenix Contact Middle East. With over 20 years of experience as a Communication Engineer in various sectors, including Service Providers, OEMs, Consulting, and utilities, he brings extensive expertise to his role. Currently, he is focusing on business development for Phoenix Contact's Communication Portfolio, which includes the RAPTOR series of products tailored for critical infrastructure applications.

Disclaimer: Phoenix Contact does not provide DPI solutions. However, the company provides a multi-services platform called Raptor, which has co-processor modules that can host third-party/vendor neural DPI solutions. These could be commercial DPI or open-source DPI solutions.

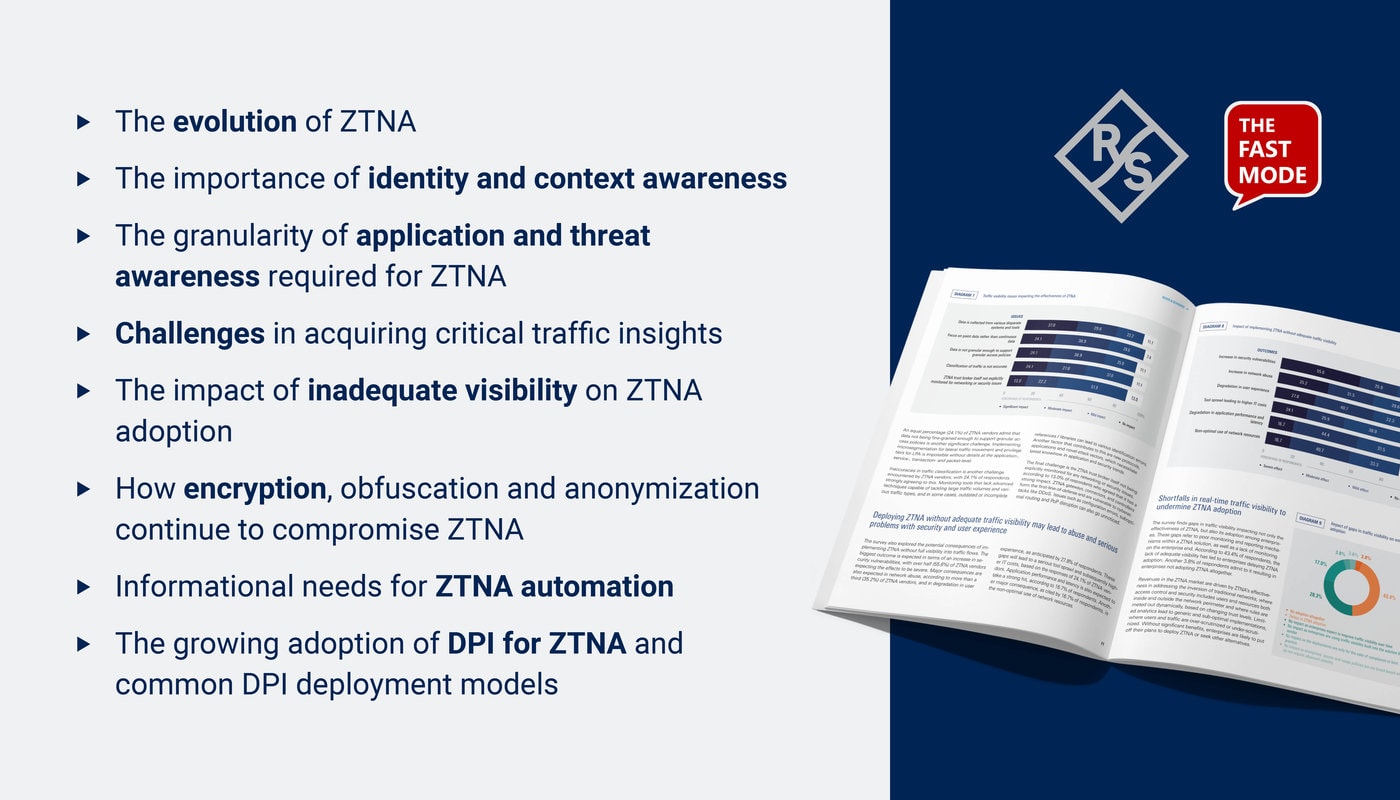

This interview is a part of The Fast Mode's Traffic Visibility segment, featuring leading networking, analytics and cybersecurity companies and their views on the importance of network intelligence and DPI for today's IP networks. A research report on this topic will be published in June 2024 - for more information, visit here.